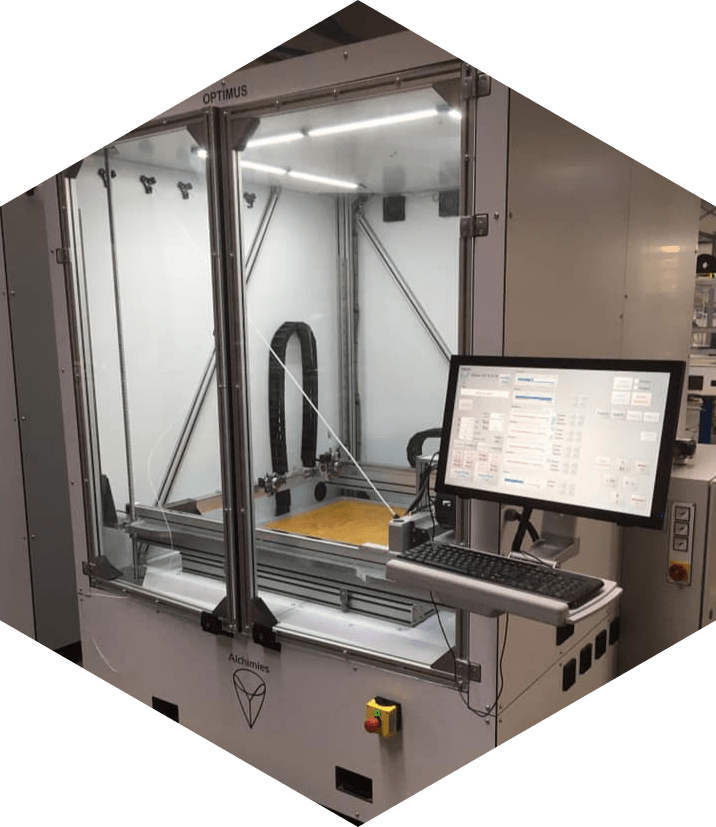

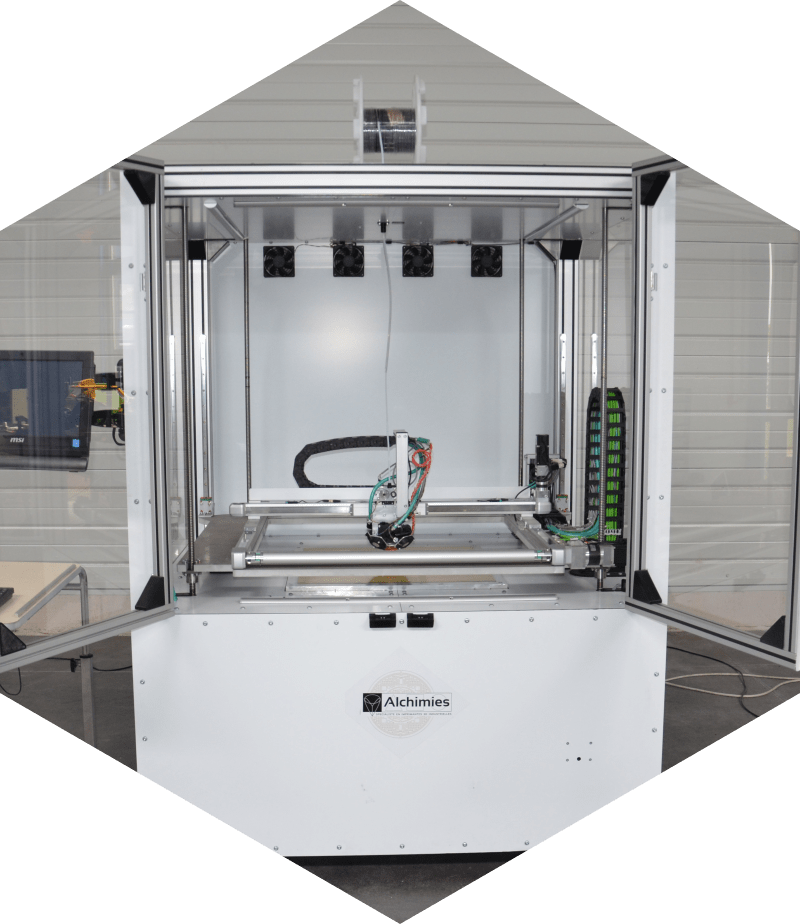

La gamme OPTIMUS

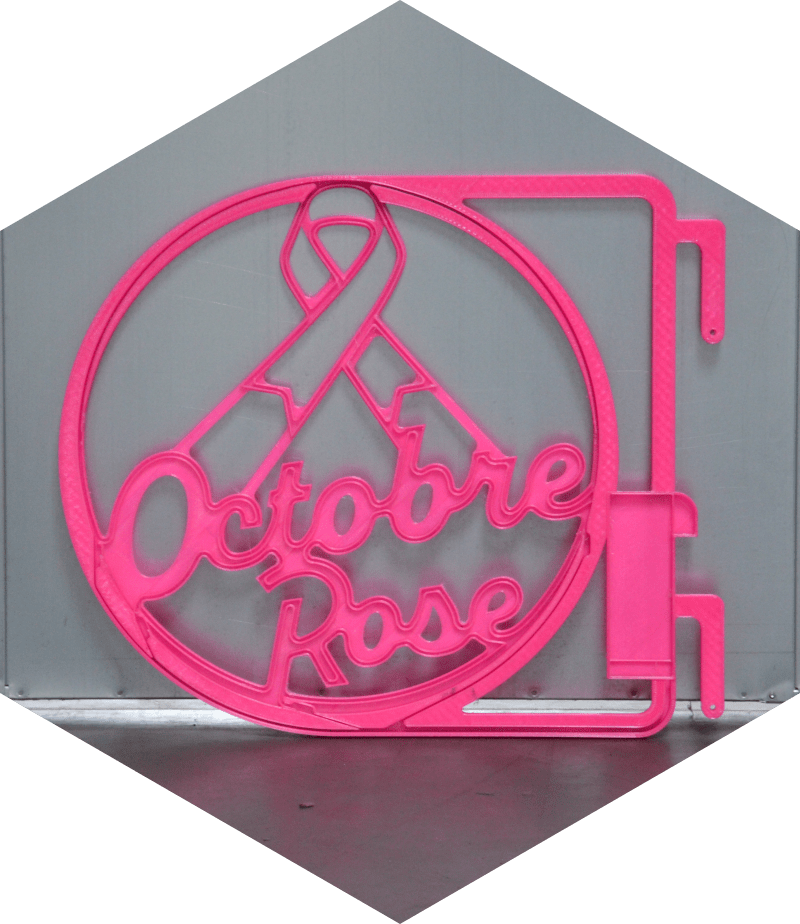

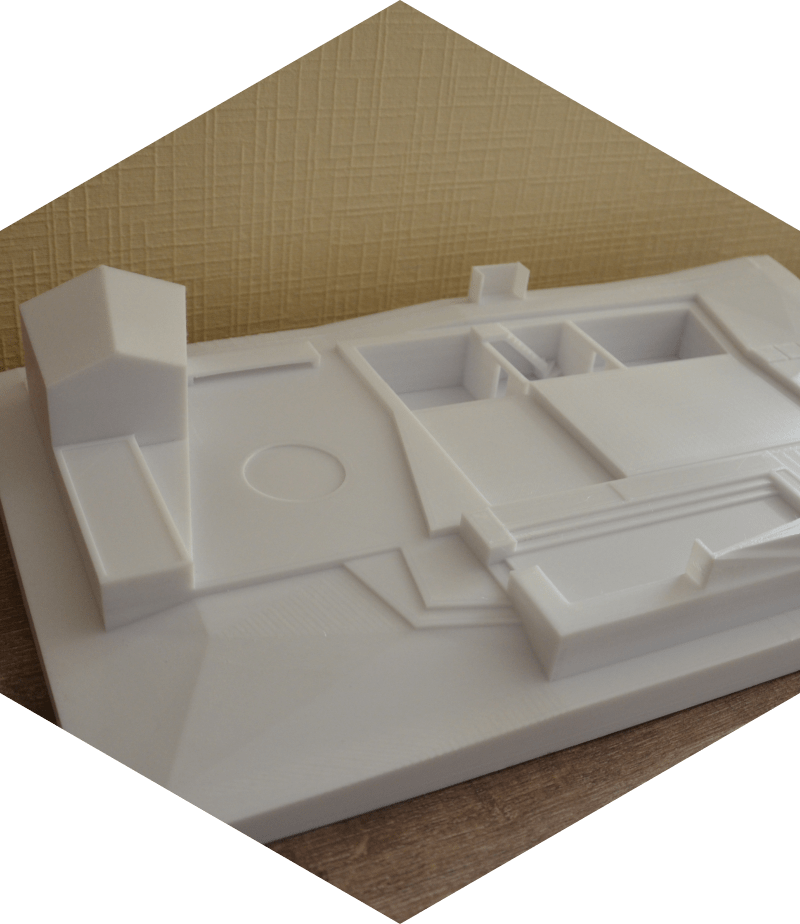

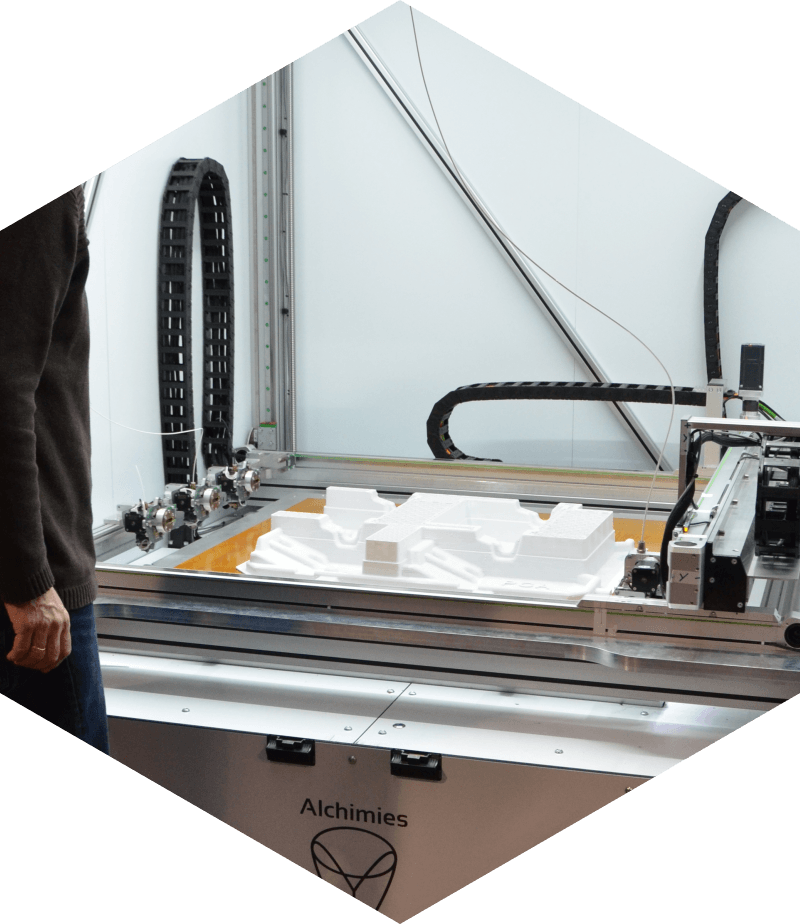

D’un volume d’impression allant jusqu’au mètre cube, la gamme Optimus se place sur le marché des imprimantes grande taille. D’ailleurs, avant l’arrivée de la gamme Evolution, elle proposait les machines les plus volumineuses conçue et fabriquées par le groupe Alchimies.

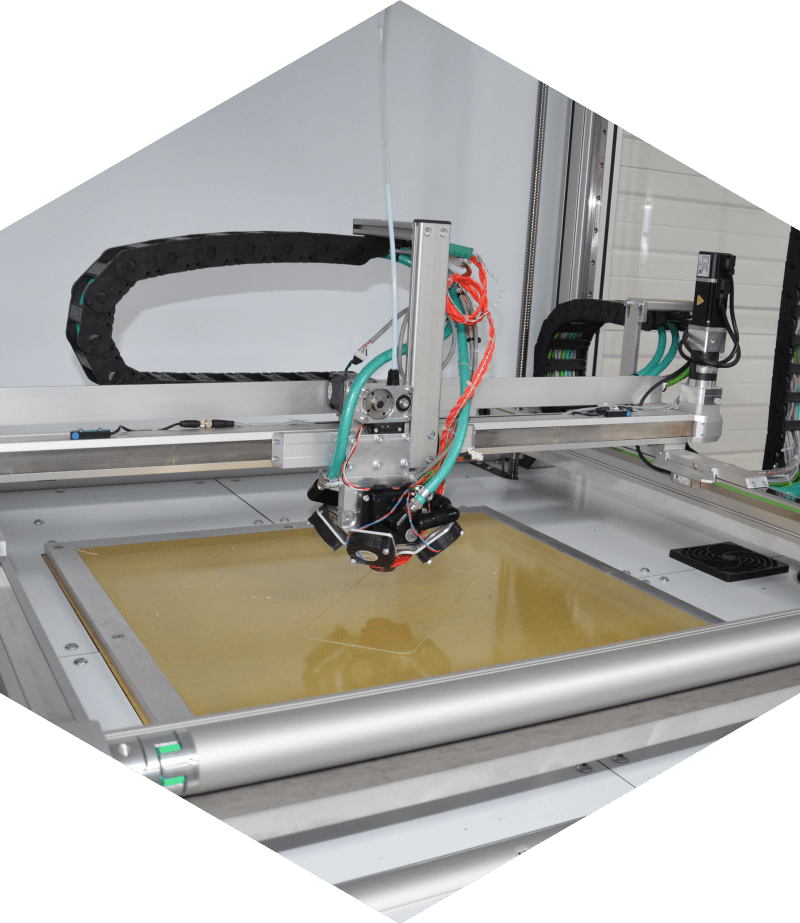

Les Optimus sont des machines industrielles capables de produire des pièces de grandes dimensions par dépôt de fil dans des matières et des tailles de tracés variées. Une grande flexibilité notamment sur le choix des têtes d’impression en font des machines polyvalente pouvant répondre à une large palette de besoin.

Fiche technique

Châssis et enceinte

Volume d’impression de 600mm x 600mm x 600mm à 1m x 1m x 1m

Structure en profilés aluminium 80mm par 80mm et 40mm par 40mm

Habillage opaque ou transparent

Multi-extrudeur avec changeur d’outils jusqu’à 4 têtes dans le magasin en option

Partie commande

Commande par carte de contrôle ou CN

Asservissement de la position des axes avec CN

Alimentation 380V (4kW)

Écran tactile 17 pouces

Ordinateur intégré à la CN

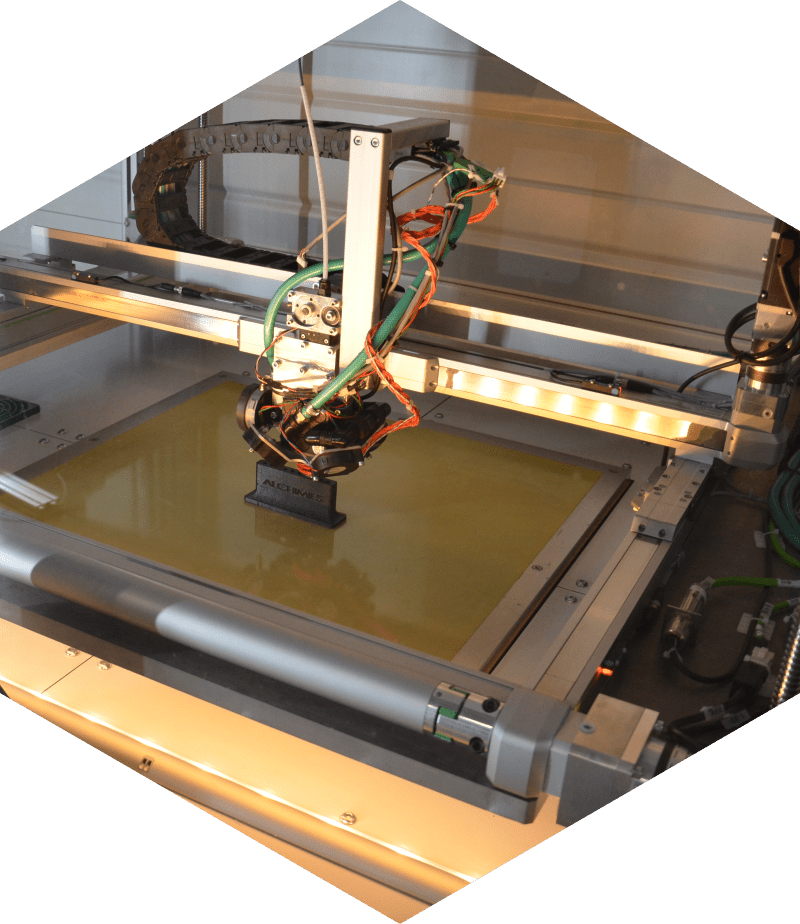

système de mouvement

Rails de guidage linéaires et vis à billes

Type de motorisation dépendant du système de contrôle

Architecture cartésienne

lit d’impression

Plaques en aluminium entre 10 et 25mm d’épaisseur selon dimensions

Surface d’impression standard en verre trempé ou PrintBite, autres nous consulter

Température maximale de 130°C

système d’extrusion thermoplastique

Extrusion direct

Différents modèles de tête d’impression adapté : filaments 1.75mm, filaments 2.85mm et granulés

Diamètres de buses entre 0.3mm et 2mm en fonction des modèles de têtes

Refroidissement tête par eau en fonction des modèles de têtes installées

Refroidissement pièce par air comprimé en fonction des modèles installées

conception modulaire

Système d’extrusion filament ou granulés au choix, autres nous consulter

Magasin changeur d’outils en option

Contactez le fabricant pour obtenir les possibilités des modèles sur-mesure.

sécurité

Arrêt d’urgence

Enceinte close en production

Verrouillage à clef des portes d’accès à la zone d’impression

Caméra de visualisation du plateau en option