La recherche au service de la formation

Le centre de recherche et de formation Open Edge accueille professionnels, demandeurs d’emploi et particuliers pour pour les faire monter en compétences dans le domaine de la fabrication additive.

Les développements et projets de recherche auxquels participe le centre viennent alimenter les contenus des programmes de formation.

Our formations

Formation des professionnels à la fabrication additive et aux procédés numériques.

Niveau : Fondamentaux – Questionner et préparer l’intégration de la Fabrication Additive (FA)

Niveau : Perfectionnement – Mette en œuvre une production par procédé d’extrusion FFF

Niveau : Expert – Pour aller plus loin sur la production par extrusion FFF

Nos formations peuvent répondre aux besoins des personnes en situation de handicap, merci de nous contacter pour discuter des aménagements physiques et organisationnels possibles.

Centre de formation accessible PMR

Le centre de formation Open Edge est accessible aux personnes à mobilité réduite.

Open Edge est certifié Qualiopi

Certification was issued under the following category of action:

TRAINING ACTIONS

Satisfaction client

Nombre de réponses (depuis mai 2022) : 72 (mis à jour le 18/04/2024)

4,6 / 5

La durée de la formation était adaptée

4,7 / 5

Les supports de formation étaient de qualité et diversifiés

4,7 / 5

Les exercices pratiques étaient pertinents

4,9 / 5

L’intervenant était compétent et à l’écoute

4,7 / 5

La training center a répondu à vos attentes

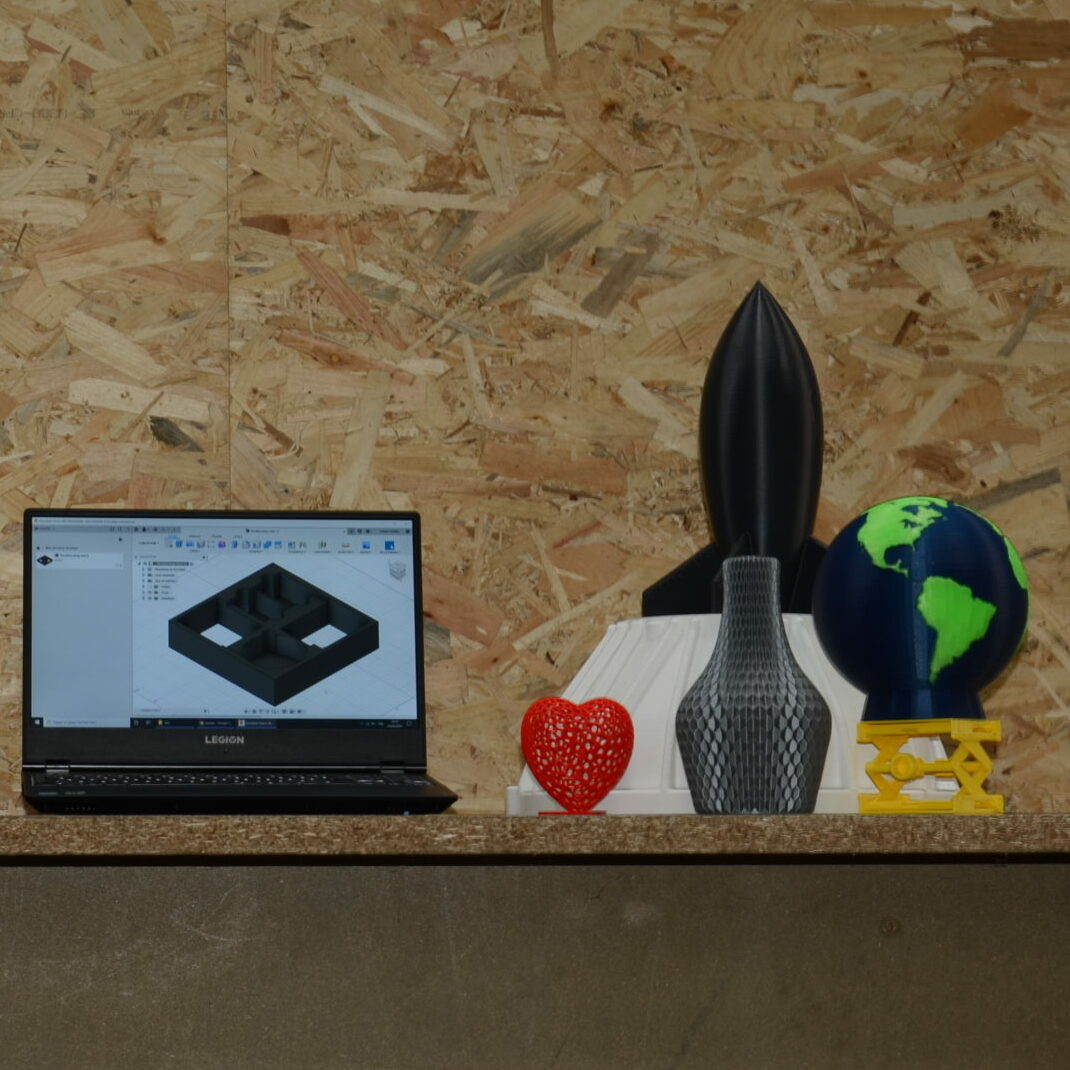

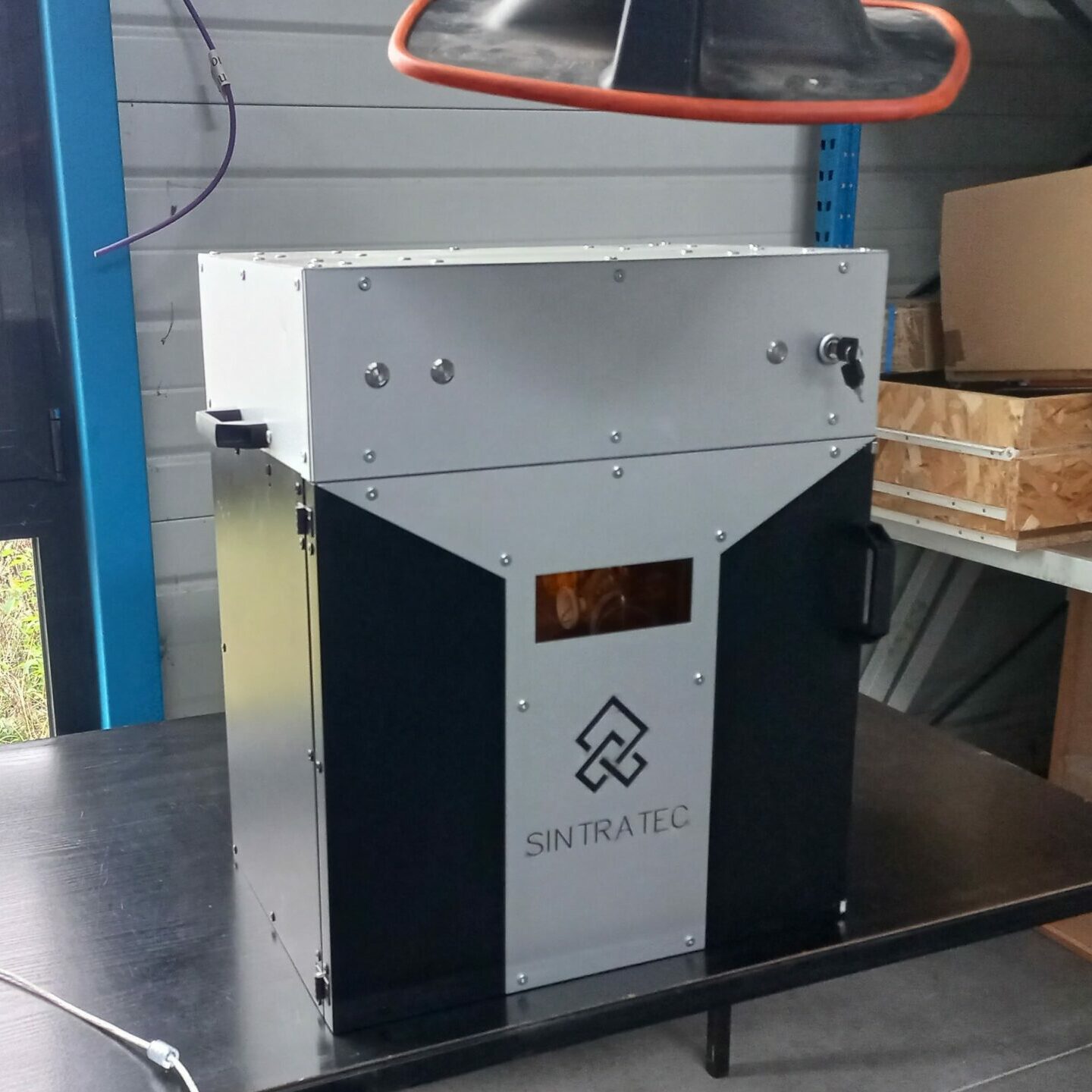

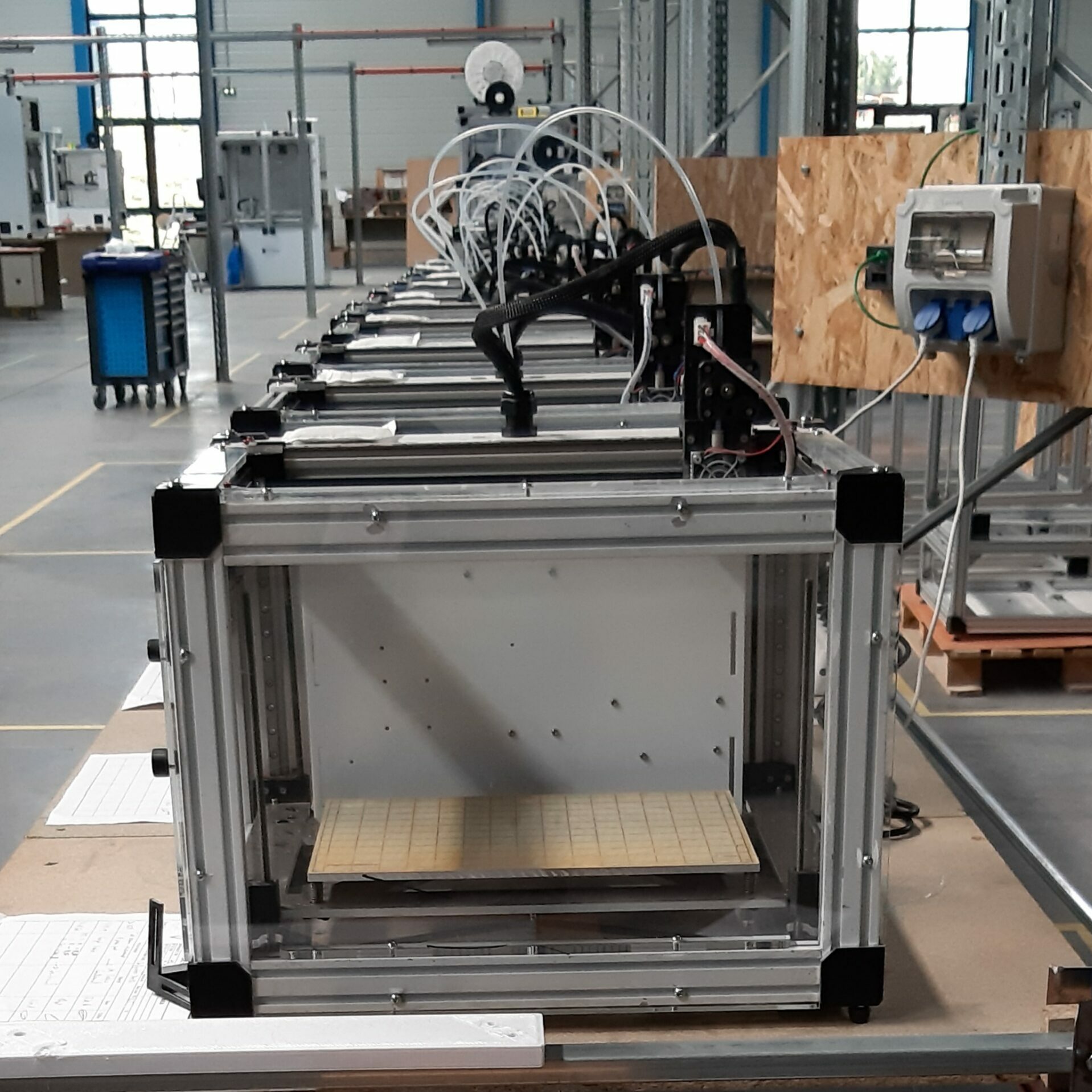

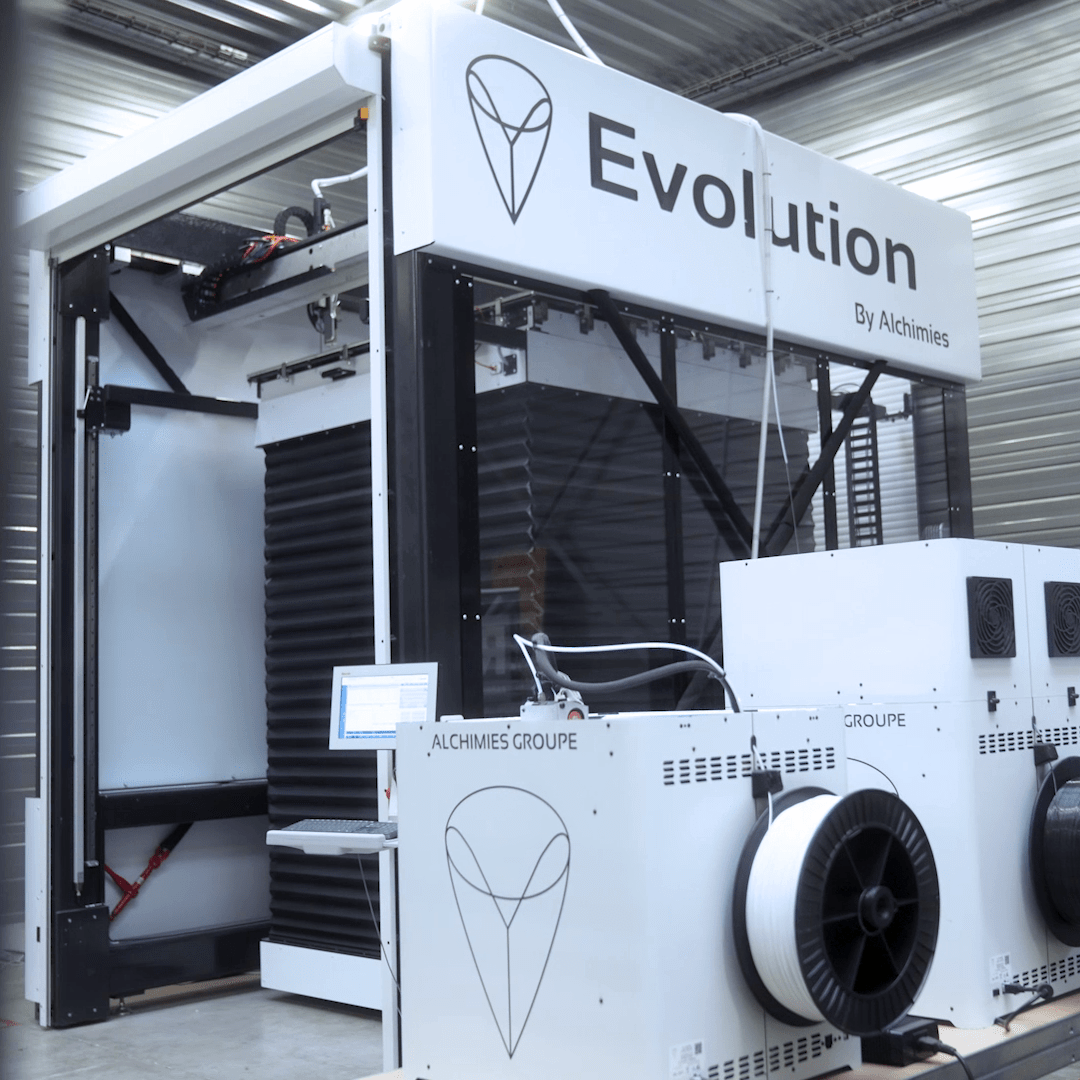

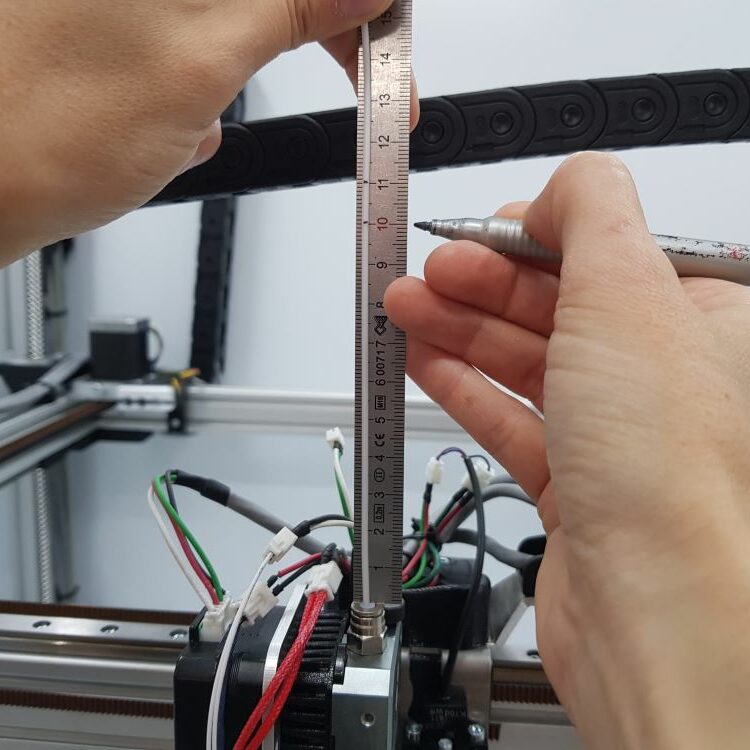

Nos équipements

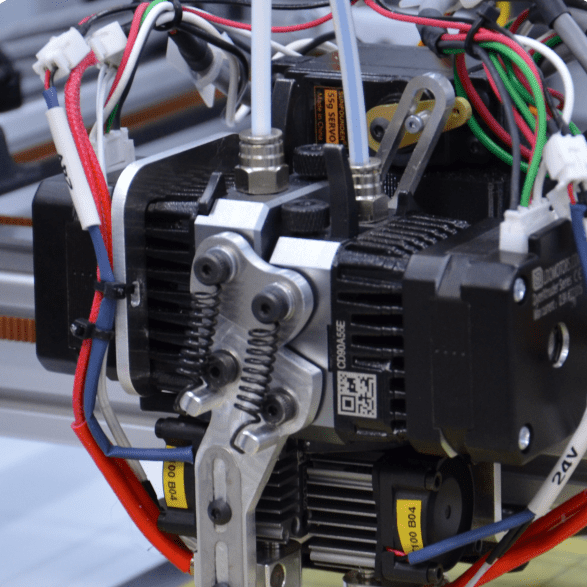

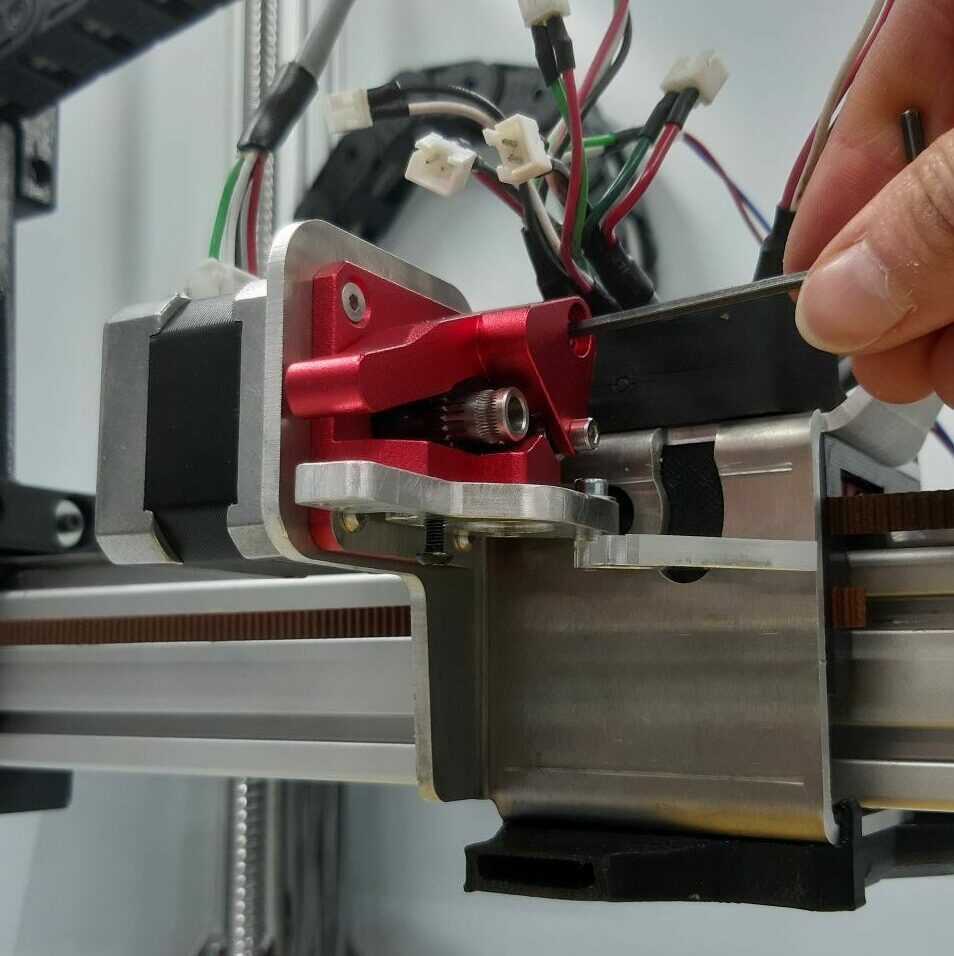

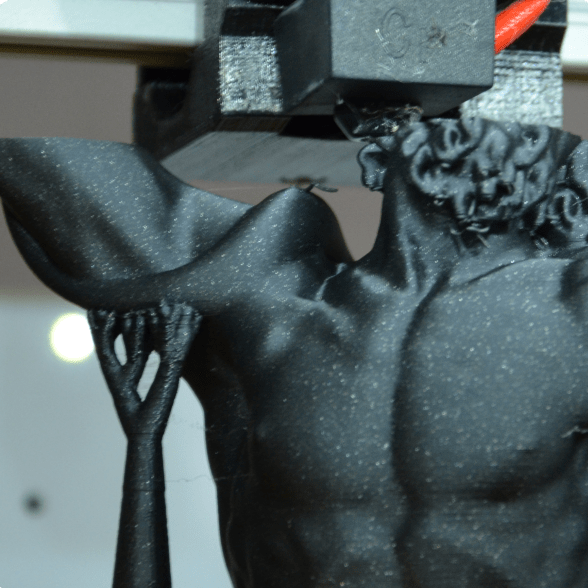

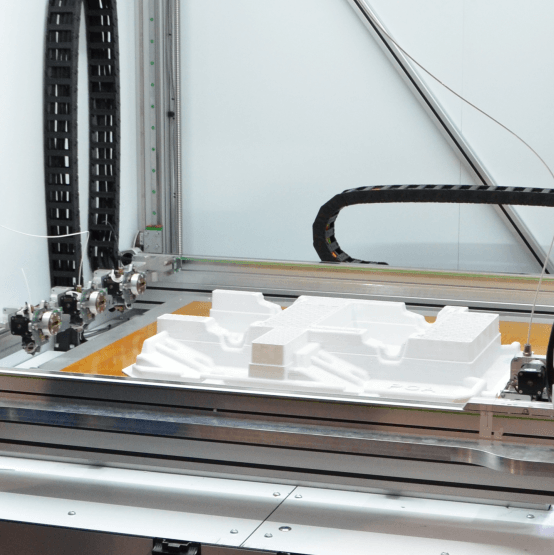

Professional FFF 3D printers

Imprimantes 3D SLA / LCD

Imprimante 3D SLS

Scanners 3D

Laser cutter

Machine à coudre et à broder

Dispositif de visio-conférence

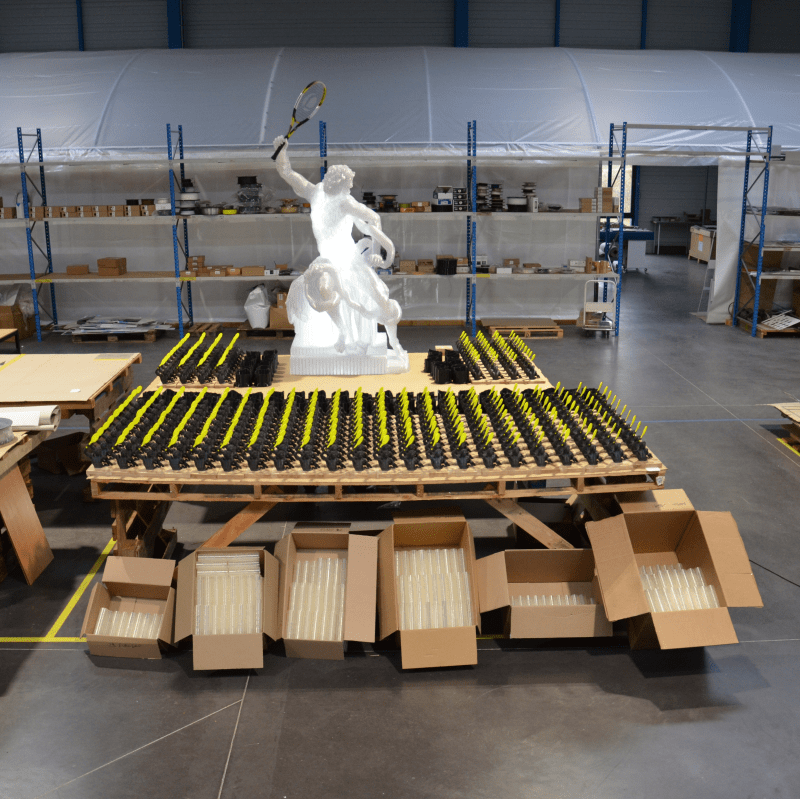

Our research participations

Participation in research projects integrating additive manufacturing and third-place approaches

e-TAC

Interfaces tangibles et augmentées pour le travail collaboratif en milieu scolaire

Grasp-it

Dispositif de rééducation du membre supérieur chez les patients post-AVC

iProduce

Plateforme de création, conception et fabrication collaborative

The Fab Living Lab

The Saulnois Fab Living Lab is a functional structure of the Saulnois Innovation third-place supported by the ASBL Saulnois Innovation. It interfaces with collaborative innovation platforms in the third place, major projects innovation focused around cutting-edge themes of the territory: agronomic & food transitions, additive manufacturing & digital processes, sustainable aquaculture & percidae farms, energy transitions & biorefinery, services, mobility & digital transitions.

C’est un centre d’innovation ouverte, un laboratoire de prototypage et de fabrication, ainsi qu’un lieu de rencontres, dont l’Université de Lorraine assure l’accompagnement scientifique

The Saulnois Fab Living Lab is an adaptation and networking of the Lorraine Fab Living Lab ® at the University of Lorraine.

Le Fab Living Lab porté par Open Edge est labellisé « Tiers-lieux Grand Est » depuis le 17 novembre 2023.

Open innovation

Par la rencontre formelle ou informelle de ses utilisateurs et visiteurs, le Fab Living Lab est un accélérateur d’innovations

Support for territorial development

Les compétences et équipements fixes ou nomades du Fab Living Lab sont au service de toute initiative de développement territorial

Think ecosystem

Chaque action menée dans ou par le Fab Living Lab est considérée dans son écosystème pour une prise en compte des enjeux de territoire

Learning by doing

Le Fab Living Lab n’a pas vocation à effectuer des prestations de service ; il accompagne les personnes dans leur apprentissage pour les rendre autonomes

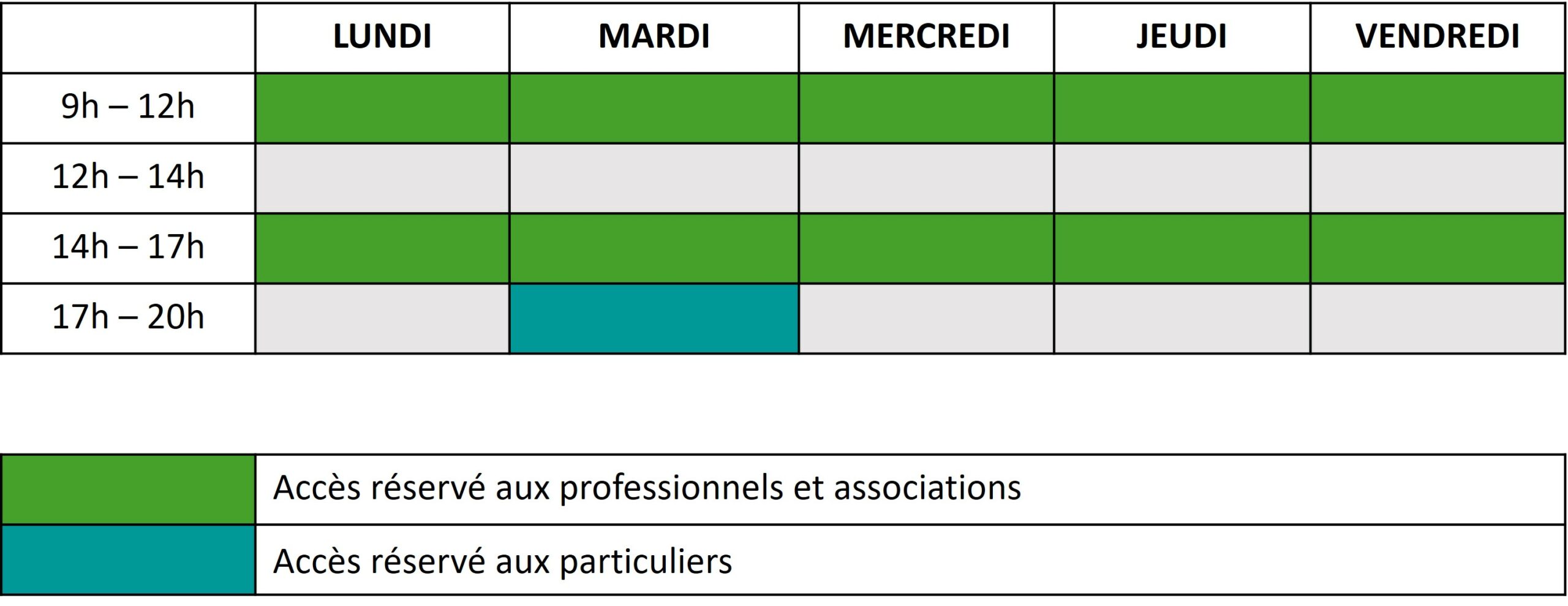

Hours and conditions of access to the Fab Living Lab

L’accès au Fab Living Lab se fait sur réservation.

L’accès en autonomie aux équipements de l’espace Fab Living Lab se fait après avoir validé une formation sur lesdits équipements.

Financial partners

Skills sponsorship